Zener Diode in Mobile Motherboard:

The Zener diode on a mobile motherboard serves several purposes:

- Voltage Regulation: Zener diodes are commonly used as voltage regulators. They maintain a constant voltage across their terminals, even when the input voltage varies. In a mobile motherboard, they help stabilize the voltage supplied to sensitive components, ensuring they receive a consistent voltage level despite fluctuations in the input voltage.

- Voltage Clamping: Zener diodes can also be used for voltage clamping, meaning they limit the voltage across a circuit to a specific level. This protects components from voltage spikes or overvoltage conditions. In a mobile motherboard, Zener diodes can protect against damage due to transient voltage spikes, which may occur, for example, during charging or when there’s a sudden surge in the power supply.

- Reverse Voltage Protection: Zener diodes can also provide reverse voltage protection by allowing current to flow in the reverse direction only when the voltage across them exceeds a certain threshold. This prevents damage to sensitive components in case of reverse polarity connections or accidental reverse voltage application.

In summary, the Zener diode on a mobile motherboard helps regulate voltage, protect against voltage spikes, and provide reverse voltage protection to ensure the proper functioning and longevity of the electronic components.

Zener Diode in Mobile Motherboard:

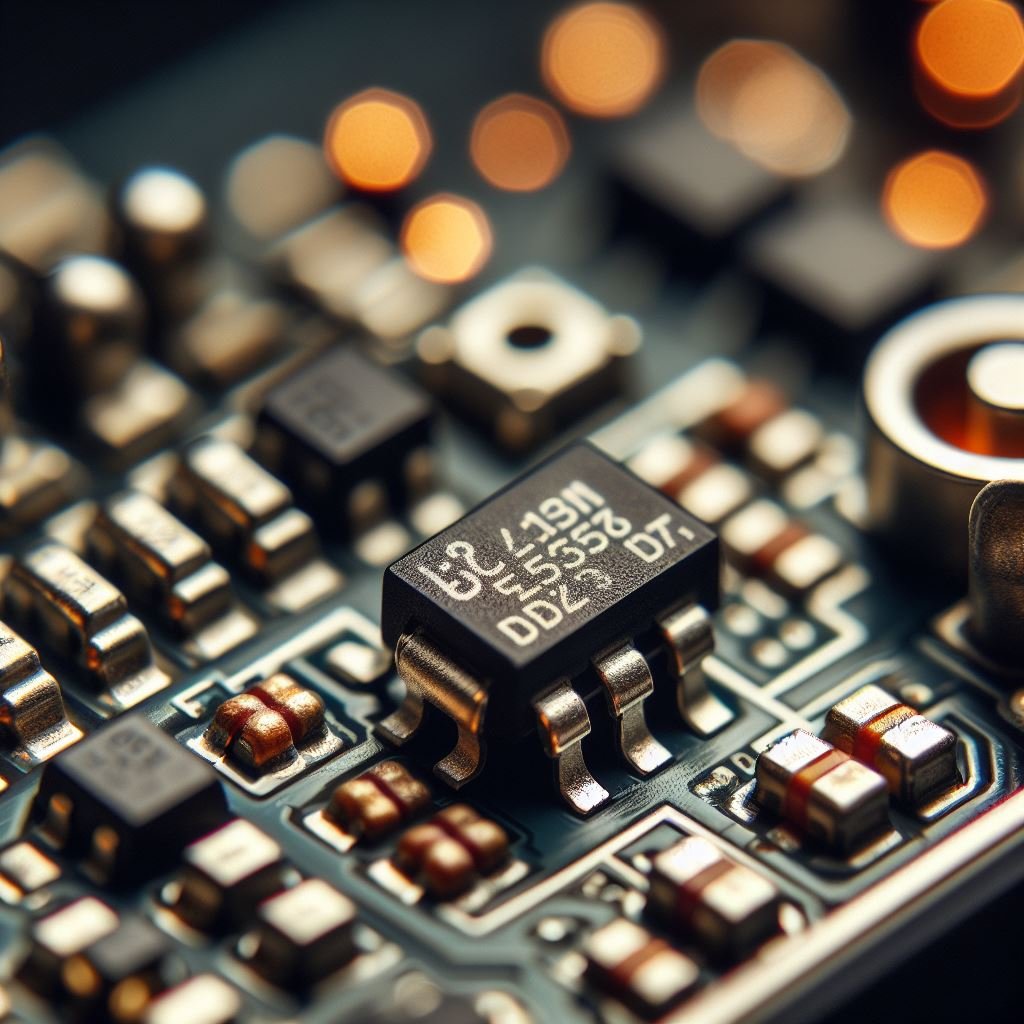

Zener diodes typically come in a small cylindrical or rectangular package, similar to standard signal diodes. They can be recognized by their distinctive markings. Here are some common characteristics:

- Package Type: Zener diodes are commonly found in packages such as DO-35, DO-41, SOD-123, SOD-323, or similar surface mount device (SMD) packages. These packages are typically small and may have a colored band at one end to indicate the cathode side.

- Markings: Zener diodes are usually marked with their part number or a code that denotes their voltage and other specifications. This marking can vary depending on the manufacturer, but it often includes a combination of letters and numbers. The voltage rating is typically indicated by a code or a numerical value followed by a letter code (e.g., “12V” or “12C”).

- Color Band: Some Zener diodes have a colored band at one end to indicate the cathode side. This band is usually black or another dark color.

- Datasheet: If you have access to the datasheet of the mobile motherboard or the specific component, it will provide detailed information about the Zener diode used, including its electrical characteristics, package type, and markings.

When identifying a Zener diode on a mobile motherboard, look for small components with markings that resemble part numbers or voltage ratings. If you’re unsure, consulting the motherboard’s schematic or datasheet can provide additional clarity. Additionally, online databases or manufacturer websites may offer resources to help identify specific components based on their markings.

Zener Diode in Mobile Motherboard:

To check whether a Zener diode is functioning correctly, you can use a multimeter in diode test mode. Here’s how you can do it:

- Set the Multimeter to Diode Test Mode: Turn on your multimeter and set it to the diode test mode. This mode is usually denoted by a diode symbol (triangle with a line) or labeled as “DIODE” on the dial.

- Identify the Cathode and Anode: If you’re testing a through-hole Zener diode with color bands, identify the cathode (usually marked by a black band) and the anode. For surface mount diodes, refer to the datasheet or markings to determine the cathode side.

- Place the Probes: Place the positive (red) probe of the multimeter on the anode side of the Zener diode and the negative (black) probe on the cathode side. Reverse the probes if you’re testing the diode in the reverse direction.

- Read the Multimeter: The multimeter will display the voltage drop across the diode. In forward bias (anode positive, cathode negative), you should typically see a voltage drop around 0.6 to 0.7 volts for a silicon diode. In reverse bias (anode negative, cathode positive), if the Zener diode is functioning correctly, you should see a voltage close to its rated Zener voltage (e.g., 5.1V, 12V, etc.). If the voltage reading is significantly different or if there’s no reading at all, the Zener diode may be faulty.

Symptoms indicating a faulty Zener diode on a mobile motherboard may include:

- Voltage Instability: Fluctuations in the voltage supplied to certain components, leading to erratic behavior or malfunction.

- Overvoltage or Undervoltage Issues: Components receiving voltages higher or lower than expected, potentially causing damage or improper operation.

- Circuit Failure: If the Zener diode fails completely, it can result in the failure of circuits dependent on its voltage regulation or protection functions.

- Visible Damage: In some cases, physical inspection may reveal signs of damage to the Zener diode, such as discoloration, cracks, or burns.

Testing the Zener diode with a multimeter can help confirm whether it’s functioning correctly and rule out potential issues with voltage regulation or protection in the circuit. If the diode fails the test or if you suspect it’s faulty based on symptoms, replacing it with a new one of the same rating is usually the recommended course of action.

Zener Diode in Mobile Motherboard:

If the Zener diode on a mobile motherboard is faulty, it can lead to various issues in the mobile device. Here are some potential problems that may arise:

- Voltage Instability: The primary function of a Zener diode is to regulate voltage. If the Zener diode fails, it may result in unstable voltage levels supplied to critical components in the mobile device. This instability can cause erratic behavior, malfunctions, or even complete failure of certain components.

- Overvoltage or Undervoltage: A faulty Zener diode may fail to regulate voltage properly, leading to overvoltage or undervoltage conditions in the mobile device. Overvoltage can damage sensitive components like microcontrollers, ICs, or memory chips. Undervoltage can cause components to malfunction or not function at all.

- Charging Issues: Zener diodes are often used in charging circuits to protect against overvoltage during charging. If the Zener diode fails in this circuit, it could lead to overcharging, which can damage the battery or other charging components.

- Power On Issues: A faulty Zener diode might prevent the device from powering on properly. This could manifest as the device not turning on at all, turning on intermittently, or shutting down unexpectedly.

- Display Problems: Voltage irregularities caused by a faulty Zener diode can affect the display module, leading to issues such as flickering, dimness, or complete failure of the display.

- Audio or Connectivity Issues: Components responsible for audio output or connectivity (such as Wi-Fi, Bluetooth, or cellular modules) may experience malfunctions due to unstable voltage supplied by a faulty Zener diode.

Overall, a faulty Zener diode can have widespread implications for the proper functioning of a mobile device, affecting various components and functionalities. If you suspect that the Zener diode is bad, it’s advisable to have it replaced or have the device inspected by a qualified technician to diagnose and rectify the issue.

Zener Diode in Mobile Motherboard:

Zener diodes and rectifier diodes are both types of semiconductor diodes, but they serve different purposes and exhibit different behaviors. Here are the key differences between them:

- Function:

- Rectifier Diode: Rectifier diodes are primarily used to convert alternating current (AC) into direct current (DC) by allowing current flow in only one direction. They are commonly used in power supply circuits to rectify AC voltage.

- Zener Diode: Zener diodes, on the other hand, are used for voltage regulation and voltage reference. They maintain a constant voltage across their terminals when operated in the reverse breakdown region. Zener diodes are commonly used in voltage regulator circuits to stabilize voltage levels.

- Operating Region:

- Rectifier Diode: Rectifier diodes typically operate in the forward bias region, allowing current flow when the voltage across them is positive.

- Zener Diode: Zener diodes operate in the reverse bias breakdown region. When the voltage across a Zener diode exceeds its breakdown voltage (known as the Zener voltage), it conducts in the reverse direction, maintaining a nearly constant voltage drop across its terminals.

- Voltage Characteristics:

- Rectifier Diode: Rectifier diodes have a forward voltage drop (VF) typically around 0.6 to 1.0 volts, depending on the material and construction.

- Zener Diode: Zener diodes have a well-defined Zener voltage (VZ) which is the voltage at which they start conducting in the reverse direction. The Zener voltage is typically specified by the manufacturer and can range from a few volts to several hundred volts.

- Applications:

- Rectifier Diode: Rectifier diodes are used in applications where AC voltage needs to be converted to DC voltage, such as in power supplies and battery chargers.

- Zener Diode: Zener diodes are used in applications where a stable reference voltage or voltage regulation is required, such as in voltage regulators, voltage clamps, and overvoltage protection circuits.

In summary, rectifier diodes are used for converting AC to DC, while Zener diodes are used for voltage regulation and reference. They operate in different bias regions and have different voltage characteristics to suit their respective applications.

Zener Diode in Mobile Motherboard:

The manufacturing process for Zener diodes, including those used in mobile motherboard circuits, involves several steps:

- Substrate Preparation: The process begins with preparing a semiconductor substrate. Zener diodes are commonly made from silicon or germanium substrates. The substrate is usually a single crystal ingot grown using techniques such as the Czochralski method.

- Doping: The substrate is doped with impurities to create the desired electrical properties. For Zener diodes, controlled doping creates a p-n junction with specific breakdown characteristics. The substrate is typically doped with donor or acceptor atoms to create an excess of either electrons (n-type) or holes (p-type) in different regions.

- Patterning: Photolithography techniques are used to define the regions where different dopants will be diffused into the substrate. A photosensitive resist is deposited and patterned with a mask, exposing areas for doping.

- Diffusion or Ion Implantation: Dopant atoms are introduced into the substrate using techniques such as diffusion or ion implantation. This process modifies the electrical properties of the substrate, creating the desired p-n junction for the Zener diode.

- Metallization: Metal contacts are deposited onto the substrate to provide electrical connections to the diode. These contacts are typically made of metals such as aluminum, gold, or copper. The metallization process involves deposition, patterning, and etching to create precise contact pads.

- Passivation: A passivation layer is applied to protect the diode from environmental factors such as moisture, contamination, and mechanical stress. This layer can be made of silicon dioxide (SiO2) or other insulating materials.

- Testing and Sorting: After fabrication, Zener diodes undergo testing to ensure they meet specifications for breakdown voltage, current handling capability, and other electrical parameters. They are sorted based on their characteristics into different bins for quality control purposes.

- Packaging: The individual Zener diodes are then packaged into housings that provide mechanical protection and facilitate connection to external circuits. Common package types include through-hole packages (e.g., DO-35, DO-41) or surface-mount packages (e.g., SOD-123, SOD-323).

Overall, the manufacturing process for Zener diodes involves precise control of doping, patterning, and metallization to create devices with specific electrical characteristics suitable for voltage regulation and reference applications in mobile motherboard circuits.

Zener Diode in Mobile Motherboard:

Zener diodes have several key characteristics that make them useful for voltage regulation and reference applications. Here are the main characteristics of Zener diodes:

- Breakdown Voltage (VZ): Zener diodes are designed to operate in the reverse breakdown region, where they maintain a nearly constant voltage across their terminals. The breakdown voltage, often denoted as VZ, is the voltage at which the Zener diode starts conducting in the reverse direction. This voltage is a crucial parameter and is specified by the manufacturer.

- Zener Impedance (Zz): Zener diodes exhibit a small dynamic resistance in the breakdown region, known as the Zener impedance (Zz). This parameter represents how the diode’s voltage varies with changes in current. A lower Zener impedance indicates better voltage regulation.

- Forward Voltage (VF): Although Zener diodes are primarily operated in the reverse direction, they still have a forward voltage drop (VF) when a small forward bias voltage is applied. This forward voltage drop is typically much lower than the breakdown voltage and can range from a few millivolts to a few tenths of a volt.

- Power Dissipation (PZ): Zener diodes have a maximum power dissipation rating, which represents the maximum amount of power they can safely dissipate without being damaged. Exceeding this rating can cause the diode to overheat and fail.

- Temperature Coefficient (αZ): The voltage of a Zener diode is affected by changes in temperature. The temperature coefficient (αZ) represents the rate of change of the Zener voltage with respect to temperature. A lower temperature coefficient indicates better temperature stability.

- Reverse Leakage Current (IR): When operated in the reverse direction below the breakdown voltage, Zener diodes exhibit a small leakage current called reverse leakage current (IR). This current should be minimal under normal operating conditions.

- Reverse Recovery Time: While not as critical for Zener diodes as for regular rectifier diodes, Zener diodes may still have a reverse recovery time, representing the time it takes for the diode to transition from the conducting state to the non-conducting state when the reverse voltage is removed.

These characteristics collectively determine the performance and suitability of a Zener diode for various voltage regulation, voltage reference, and overvoltage protection applications. Different Zener diode models may have varying specifications for these parameters, so it’s essential to select a diode with characteristics that match the requirements of the specific circuit or application.

Zener Diode in Mobile Motherboard:

Zener diodes used in mobile motherboards, like many electronic components, are manufactured by various semiconductor companies worldwide. Some of the well-known semiconductor manufacturers that produce Zener diodes suitable for mobile motherboard applications include:

- Vishay Intertechnology

- ON Semiconductor

- STMicroelectronics

- Diodes Incorporated

- NXP Semiconductors

- ROHM Semiconductor

- Toshiba Electronic Devices & Storage Corporation

- Infineon Technologies

- Fairchild Semiconductor (now part of ON Semiconductor)

- Central Semiconductor Corp.

These companies produce a wide range of Zener diodes with different voltage ratings, power dissipation capabilities, package types, and other specifications to meet the diverse needs of mobile device manufacturers and other electronics industries. Mobile motherboard manufacturers typically select Zener diodes based on factors such as performance requirements, cost, availability, and supplier relationships.

Protecting the Zener diode on a mobile motherboard involves implementing measures to prevent it from experiencing conditions that could lead to damage or malfunction. Here are some steps to protect the Zener diode:

- Proper Circuit Design: Ensure that the Zener diode is properly integrated into the circuit design with appropriate voltage levels, current limits, and protection features.

- Overvoltage Protection: Implement overvoltage protection circuits such as transient voltage suppressors (TVS), metal-oxide varistors (MOV), or clamping diodes to prevent excessive voltage spikes from reaching the Zener diode during transient events like electrostatic discharge (ESD), lightning strikes, or voltage surges.

- Current Limiting: Use resistors or current-limiting devices in series with the Zener diode to prevent excessive current flow through it, especially during transient events or overloads.

- Thermal Management: Ensure proper thermal management to prevent the Zener diode from overheating. Adequate heat sinking, airflow, or temperature monitoring can help maintain the Zener diode within its specified operating temperature range.

- Reverse Polarity Protection: Implement reverse polarity protection to prevent damage to the Zener diode in case of accidental reverse voltage connection.

- Isolation: Isolate sensitive components and circuits from potentially harmful electrical disturbances or noise sources to minimize the risk of damage to the Zener diode.

- Quality Control: Ensure that the Zener diode and associated components are of high quality and meet the required specifications. Perform regular quality control checks during manufacturing to identify any potential issues early on.

- Compliance with Standards: Ensure compliance with relevant industry standards and regulations for electronic components and circuits to ensure safety and reliability.

- Testing and Monitoring: Regularly test and monitor the performance of the Zener diode and associated circuits to detect any anomalies or signs of degradation. This can include functional testing, electrical testing, and reliability testing.

By implementing these protective measures, you can help safeguard the Zener diode on the mobile motherboard and ensure reliable performance under various operating conditions.

Read More Interesting Story:

https://dotparks.com/football-game/

https://dotparks.com/transformers/

https://dotparks.com/ludo-game/

Your article helped me a lot, is there any more related content? Thanks!

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://accounts.binance.com/register?ref=P9L9FQKY

whoah this blog is magnificent i really like reading your posts. Keep up the great work! You know, many persons are searching round for this information, you could aid them greatly.

эскорт

Your article helped me a lot, is there any more related content? Thanks!