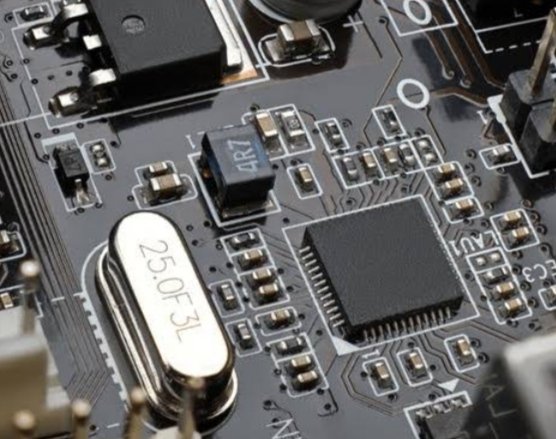

Crystal Oscillator at Mobile Motherboard Circuit:

The crystal oscillator on a mobile motherboard serves as a precision timing device that generates stable and accurate clock signals. These clock signals are essential for synchronizing various operations and functions within the mobile device’s circuitry, including data processing, communication, and power management.

Here’s how the crystal oscillator works and its role in a mobile motherboard:

- Oscillation: The crystal oscillator circuit consists of a crystal resonator (typically made of quartz) and associated electronic components. When a voltage is applied to the crystal, it vibrates at its natural resonant frequency, generating an oscillating electrical signal. The frequency of oscillation is determined by the physical characteristics of the crystal, such as its size, shape, and cut.

- Clock Generation: The oscillating signal produced by the crystal oscillator circuit serves as a stable reference frequency, which is used to generate precise clock signals for various components and circuits within the mobile device. These clock signals provide timing information for tasks such as data processing, memory access, display refresh, and wireless communication.

- Frequency Stability: One of the key advantages of using a crystal oscillator is its high frequency stability and accuracy. Quartz crystals exhibit minimal frequency drift over time and temperature variations, making them ideal for applications that require precise timing, such as mobile devices.

- Low Phase Noise: Crystal oscillators typically produce low phase noise, which is essential for maintaining signal integrity and minimizing interference in sensitive communication and processing circuits. This helps ensure reliable performance and efficient operation of the mobile device.

- Frequency Adjustment: In some cases, the frequency of the crystal oscillator can be adjusted using external circuitry or control signals. This allows for fine-tuning of the clock frequency to meet specific performance requirements or to synchronize with external timing sources.

Overall, the crystal oscillator plays a critical role in the operation of a mobile motherboard by providing stable and accurate timing signals for the device’s various components and functions. Its precise timing capabilities are essential for ensuring reliable performance and efficient operation of the mobile device.

Crystal Oscillator at Mobile Motherboard Circuit:

The crystal oscillator on a mobile motherboard functions as a timing reference generator, providing precise clock signals for various components and circuits within the device. Here’s how it works and how it’s typically connected within the motherboard’s circuitry:

- Oscillation Principle: The crystal oscillator circuit consists of a quartz crystal resonator and associated electronic components. When voltage is applied to the crystal, it undergoes mechanical deformation due to the piezoelectric effect, vibrating at its natural resonant frequency. This vibration generates an oscillating electrical signal.

- Frequency Determination: The frequency of oscillation is primarily determined by the physical characteristics of the quartz crystal, including its size, shape, and cut. Quartz crystals are selected to resonate at specific frequencies, typically in the MHz (megahertz) range, depending on the requirements of the mobile device.

- Clock Generation: The oscillating signal produced by the crystal oscillator serves as a stable reference frequency, which is used to generate precise clock signals for various components and circuits within the mobile motherboard. These clock signals synchronize the operation of the device’s processor, memory, peripherals, and communication interfaces.

- Connection to Components: The crystal oscillator is typically connected to other components and circuits within the motherboard through signal traces or conductive pathways on the printed circuit board (PCB). The clock signals generated by the crystal oscillator are distributed to the relevant components using routing and interconnects on the PCB.

- Frequency Adjustment and Control: In some cases, the frequency of the crystal oscillator can be adjusted or controlled using external circuitry or control signals. This allows for fine-tuning of the clock frequency to meet specific performance requirements or to synchronize with external timing sources.

- Clock Distribution: The clock signals generated by the crystal oscillator may be distributed to various components and circuits using clock distribution networks, such as clock buffers, dividers, or multiplexers. These circuits ensure that each component receives the appropriate timing signals according to its operational requirements.

Overall, the crystal oscillator on a mobile motherboard plays a crucial role in providing stable and accurate timing signals for the device’s operation. Its proper connection and integration within the motherboard’s circuitry are essential for ensuring reliable performance and efficient operation of the mobile device.

Crystal Oscillator at Mobile Motherboard Circuit:

The voltage supplied by a crystal oscillator on a mobile motherboard typically depends on the specific design and requirements of the oscillator itself, as well as the surrounding circuitry. Crystal oscillators for mobile devices are typically powered by low voltage sources to ensure compatibility with the device’s power management system and other components.

In most cases, crystal oscillators for mobile motherboards are designed to operate within the voltage range provided by the device’s power supply, which is typically between 1.8 volts and 3.3 volts for modern mobile devices. However, the actual voltage supplied by the crystal oscillator may vary depending on factors such as the specific design specifications, manufacturer recommendations, and the operating conditions of the device.

It’s essential to ensure that the voltage supplied to the crystal oscillator falls within its specified operating range to ensure proper operation and reliability. Excessive voltage can lead to overdriving or damaging the oscillator, while insufficient voltage may result in unreliable performance or failure to oscillate.

Therefore, when designing or troubleshooting mobile motherboard circuits involving crystal oscillators, it’s crucial to adhere to the recommended voltage specifications provided by the oscillator manufacturer and ensure compatibility with the device’s power supply system.

Crystal Oscillator at Mobile Motherboard Circuit:

The crystal oscillator on a mobile motherboard typically appears as a small, rectangular or square-shaped component with metal leads for soldering onto the motherboard’s circuitry. Here are some common characteristics of crystal oscillators:

- Size: Crystal oscillators are relatively small components due to space constraints on mobile motherboards. They typically have dimensions ranging from a few millimeters to a few centimeters, depending on the specific design and manufacturer.

- Shape: Crystal oscillators can have various shapes, but they are commonly rectangular or square in appearance. The shape often depends on the packaging used by the manufacturer and the requirements of the application.

- Metal Casing: Crystal oscillators are often enclosed in a metal casing for protection against external interference and mechanical damage. The casing may be square or rectangular, matching the outer dimensions of the oscillator component.

- Markings: Crystal oscillators may have markings printed directly on the metal casing or on a label attached to the component. These markings typically include information such as the manufacturer’s logo, part number, frequency, voltage rating, and other specifications. However, the presence and visibility of markings can vary depending on the manufacturer and the specific design of the oscillator.

Recognizing a crystal oscillator on a mobile motherboard may require careful inspection and identification of nearby components. Some common locations for crystal oscillators on mobile motherboards include near the processor, memory modules, or wireless communication modules.

If markings are present, they can provide valuable information about the specifications and compatibility of the crystal oscillator. However, if no markings are visible or if additional information is needed, referring to the device’s technical documentation or contacting the manufacturer may be necessary to determine the exact specifications of the crystal oscillator.

Crystal Oscillator at Mobile Motherboard Circuit:

If the crystal oscillator on a mobile motherboard is faulty or malfunctioning, it can lead to various issues with the functioning of the mobile device. Here are some potential problems that may arise:

- Failure to Power On: The crystal oscillator provides timing signals critical for the device’s operation. If the oscillator is faulty, the device may fail to power on or boot up properly.

- System Instability: A malfunctioning crystal oscillator can cause the system to operate at incorrect frequencies or produce unstable clock signals. This can lead to system crashes, freezes, or erratic behavior while using the device.

- Loss of Connectivity: Crystal oscillators are often used in wireless communication circuits to generate clock signals for Wi-Fi, Bluetooth, or cellular modules. If the oscillator is faulty, it can lead to loss of connectivity or poor signal quality.

- Display Issues: Crystal oscillators are also used in display circuits to generate timing signals for the screen refresh rate. A faulty oscillator can result in display flickering, artifacts, or improper synchronization with the device’s graphics processor.

- Memory and Storage Errors: Crystal oscillators are crucial for timing-sensitive operations, such as accessing memory or storage devices. A malfunctioning oscillator can lead to errors or data corruption when accessing RAM, flash memory, or storage drives.

- Peripheral Malfunction: Some peripherals, such as USB interfaces or sensors, may rely on accurate timing signals from the crystal oscillator. If the oscillator is faulty, it can cause peripherals to malfunction or fail to communicate properly with the device.

- Battery Drain: In some cases, a faulty crystal oscillator may cause the device to consume more power than usual, leading to rapid battery drain or reduced battery life.

If you suspect that the crystal oscillator on your mobile motherboard is faulty, it’s essential to have it diagnosed and replaced by a qualified technician to restore the proper functioning of the device.

Crystal Oscillator at Mobile Motherboard Circuit:

The crystal oscillator on a mobile motherboard is made using precise manufacturing processes to ensure its accuracy and reliability. Here’s an overview of how crystal oscillators are typically made:

- Quartz Crystal Selection: The first step in manufacturing a crystal oscillator is selecting a quartz crystal with the desired frequency characteristics. Quartz crystals are naturally occurring minerals that exhibit piezoelectric properties, meaning they generate an electrical signal when subjected to mechanical stress. The specific cut and orientation of the crystal are chosen to provide the desired resonant frequency for the oscillator.

- Crystal Mounting: The quartz crystal is mounted onto a substrate or base material using specialized bonding techniques. The mounting process ensures that the crystal is securely attached and properly aligned for optimal performance.

- Electrode Deposition: Electrodes are deposited onto the surface of the quartz crystal to provide electrical connections for the oscillator circuit. These electrodes are typically made of metals such as silver or gold and are patterned using techniques such as sputtering, evaporation, or plating.

- Encapsulation: The crystal oscillator assembly is encapsulated in a protective housing or package to shield it from external interference and mechanical damage. The encapsulation material is typically an epoxy resin or ceramic material that provides insulation and protection for the delicate components inside.

- Wiring and Connections: The electrodes on the crystal are connected to external terminals or leads for integration into the mobile motherboard circuitry. These connections are typically made using wire bonding or soldering techniques to ensure reliable electrical contact.

- Testing and Calibration: Once assembled, the crystal oscillator undergoes rigorous testing and calibration to verify its frequency stability, accuracy, and reliability. Testing may include measuring the frequency response, temperature stability, phase noise, and other performance parameters to ensure compliance with specifications.

- Quality Control: Throughout the manufacturing process, strict quality control measures are implemented to ensure that the crystal oscillator meets the specified requirements for performance and reliability. This may include inspection of materials, assembly processes, and final testing to identify and rectify any defects or deviations from standards.

Overall, the manufacturing process for a crystal oscillator involves precise fabrication techniques and quality control measures to produce a reliable timing device suitable for use in mobile motherboards and other electronic devices.

Crystal Oscillator at Mobile Motherboard Circuit:

Crystal oscillators for mobile motherboards are typically manufactured by specialized electronic component companies that produce a wide range of passive and active components for various industries, including the telecommunications and consumer electronics sectors. These companies often supply components to mobile device manufacturers as part of their supply chain. Some well-known manufacturers of crystal oscillators and related components include:

- Kyocera Corporation

- Murata Manufacturing Co., Ltd.

- Epson Toyocom Corporation (Seiko Epson Corporation)

- Abracon LLC

- TXC Corporation

- Rakon Limited

- NDK (Nihon Dempa Kogyo Co., Ltd.)

- SiTime Corporation

These companies have extensive experience and expertise in designing and manufacturing crystal oscillators for various applications, including mobile devices. They offer a variety of crystal oscillator types, sizes, frequencies, and specifications to meet the diverse requirements of mobile motherboard designs.

Mobile device manufacturers typically source crystal oscillators from these specialized suppliers to ensure the quality, reliability, and performance of their products. These manufacturers often work closely with oscillator suppliers to select components that meet their specific design requirements and performance criteria.

Crystal Oscillator at Mobile Motherboard Circuit:

To protect the crystal oscillator on a mobile motherboard and ensure its proper functioning, several measures can be taken:

- Physical Protection: Encapsulate the crystal oscillator in a protective housing or package to shield it from mechanical damage, moisture, and environmental contaminants. The protective casing should provide adequate insulation and support for the delicate components inside.

- EMI Shielding: Implement electromagnetic interference (EMI) shielding measures to protect the crystal oscillator from external electromagnetic interference, which can degrade its performance or introduce noise into the signal. This may involve using shielding materials such as metal enclosures or conductive coatings.

- Temperature Control: Ensure that the operating temperature of the crystal oscillator remains within the specified range to maintain its frequency stability and accuracy. Use thermal management techniques such as heat sinking, ventilation, or temperature compensation circuits to regulate the temperature around the oscillator.

- Voltage Regulation: Provide stable and clean power to the crystal oscillator to prevent voltage fluctuations or noise from affecting its performance. Use voltage regulation circuits, filtering capacitors, and decoupling techniques to minimize electrical interference and maintain a consistent voltage level.

- Overcurrent Protection: Incorporate overcurrent protection mechanisms, such as fuses or current-limiting resistors, in the circuitry to prevent excessive current from damaging the crystal oscillator. This can help safeguard the oscillator against electrical faults or short circuits.

- Clock Distribution: Implement proper clock distribution networks to ensure that the crystal oscillator’s clock signals are routed effectively to the relevant components and circuits within the mobile motherboard. Use low-impedance signal traces, buffer amplifiers, and signal conditioning circuits to maintain signal integrity and minimize noise.

- Quality Control: Perform rigorous testing and quality control measures during the manufacturing process to ensure that the crystal oscillator meets specified performance and reliability standards. This may include testing for frequency stability, temperature tolerance, phase noise, and other key parameters.

- Regular Maintenance: Periodically inspect the crystal oscillator and surrounding circuitry for signs of damage, wear, or degradation. Perform preventive maintenance as needed to address any issues and ensure the continued reliability of the oscillator.

By implementing these protective measures, you can help safeguard the crystal oscillator on the mobile motherboard and ensure its reliable operation within the device’s circuitry

Read More Interesting Story:

https://dotparks.com/football-game/

https://dotparks.com/transformers/

https://dotparks.com/ludo-game/

https://dotparks.com/capacitor/

https://dotparks.com/what-is-transistor/

Hey there! dotparks.com

Did you know that it is possible to send message solely legit? We propose a novel method of transmitting commercial offers via contact forms.

Contact Form messages are usually not sent to spam, since they are considered to be important.

You can use our service with no cost to you.

We can deliver up to 50,000 messages to you.

The cost of sending one million messages is $59.

This message was automatically generated.

We only use chat for communication.

Contact us.

Telegram – https://t.me/FeedbackFormEU

Skype live:contactform_18

WhatsApp – +375259112693

WhatsApp https://wa.me/+375259112693