Coil For Mobile Repairing:

The coil, also known as an inductor, on a mobile motherboard serves several functions depending on its specific application within the circuitry. Here are some common roles of coils on mobile motherboards:

- Filtering and Decoupling: Coils are often used in conjunction with capacitors to filter out high-frequency noise or ripple voltage from the power supply. They help smooth the DC voltage and provide stable power to sensitive components such as the CPU, GPU, and memory.

- Voltage Regulation: In voltage regulator circuits, coils can be used to step up or step down the voltage level as needed. For example, in DC-DC converters, coils are used to convert the input voltage to the desired output voltage.

- Signal Processing: Coils can be employed in signal processing circuits, such as RF (Radio Frequency) circuits used for wireless communication. They help tune the frequency of signals, filter out unwanted frequencies, or amplify weak signals.

- Energy Storage: Coils store energy in the form of a magnetic field when current flows through them. This stored energy can be released when the current is interrupted, providing a buffer against sudden changes in power demand or voltage spikes.

- EMI Suppression: Coils can help suppress electromagnetic interference (EMI) generated by the circuit or external sources. They act as filters, blocking high-frequency noise from reaching sensitive components and reducing electromagnetic radiation emitted by the device.

Overall, coils play a crucial role in the operation and performance of mobile motherboards by providing power conditioning, signal processing, and electromagnetic compatibility (EMC) functions. Their design and placement within the circuitry are carefully optimized to ensure the reliable operation of the mobile device.

Coil For Mobile Repairing:

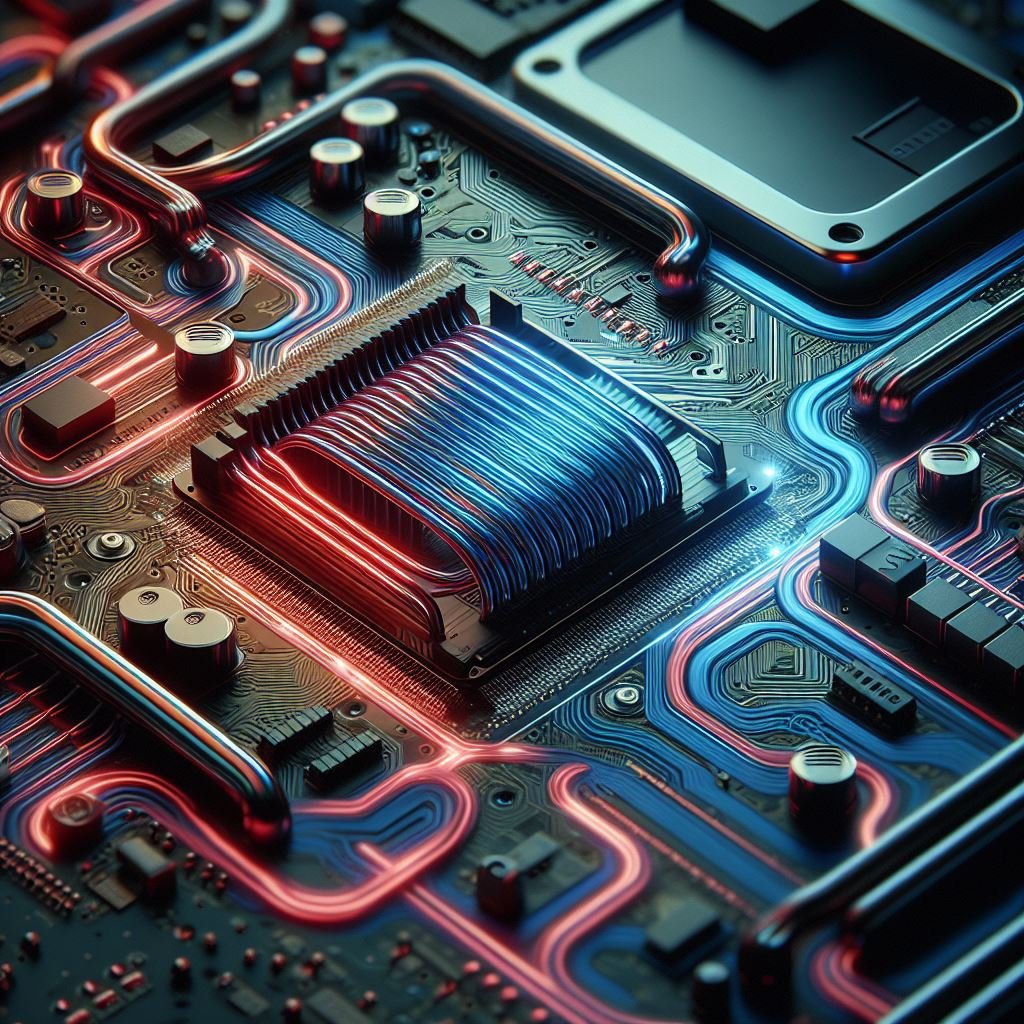

The coil, also known as an inductor or choke, on a mobile motherboard works based on the principles of electromagnetic induction. Here’s how it functions and how it’s typically connected within the circuitry:

- Inductance: An inductor is a passive electronic component that stores energy in a magnetic field when current flows through it. The amount of energy stored is proportional to the current passing through the coil and the number of turns of wire in the coil.

- Energy Storage: When a current flows through the coil, it generates a magnetic field around the coil. This magnetic field stores energy. When the current flowing through the coil changes, the magnetic field collapses, releasing the stored energy back into the circuit.

- Inductive Reactance: Inductors exhibit a property called inductive reactance, which is a form of opposition to changes in current flow. This property makes inductors useful in various applications, including filtering out high-frequency noise in power supplies or blocking alternating current while allowing direct current to pass.

- Filtering and Regulation: In mobile motherboard circuits, coils are often used in conjunction with capacitors to create filters that smooth out voltage or current fluctuations. They can also be used in voltage regulation circuits to stabilize the output voltage.

In terms of how the coil is connected within the circuitry:

- Series Connection: In many cases, the coil is connected in series with other components in the circuit. For example, in a voltage regulation circuit, the coil might be connected in series with a voltage regulator and capacitors to filter out noise and stabilize the output voltage.

- Parallel Connection: Coils can also be connected in parallel with other components, such as capacitors or resistors, to form resonant circuits or impedance-matching networks. In RF circuits, for instance, coils may be connected in parallel with capacitors to create tuned circuits for filtering specific frequencies.

Overall, the coil on a mobile motherboard serves various functions depending on its specific application within the circuit. Its proper connection and integration within the circuitry are essential for ensuring the reliable operation of the mobile device.

Coil For Mobile Repairing:

The voltage supplied or regulated by the coil on a mobile motherboard depends on its specific application within the circuitry. Coils, also known as inductors, can be used for various purposes, including voltage regulation, filtering, and signal processing.

In voltage regulation circuits, the coil may be part of a voltage regulator circuit that stabilizes the output voltage. The output voltage of such circuits can vary depending on the design and requirements of the mobile device. For example, in typical mobile devices, voltage regulators may be used to maintain stable voltage levels for components such as the processor, memory, or display. The voltage levels for these components can vary, but they commonly fall within the range of a few volts to several volts.

In other applications, such as signal processing circuits or filtering circuits, the voltage across the coil may also vary depending on the specific signals being processed or filtered. In these cases, the coil’s role may be to pass or block certain frequencies, rather than directly regulate voltage.

Therefore, the voltage supplied or regulated by the coil on a mobile motherboard can vary widely depending on its specific function and the overall design of the circuitry. It is typically determined by the requirements of the components or signals being processed within the circuit.

Coil For Mobile Repairing:

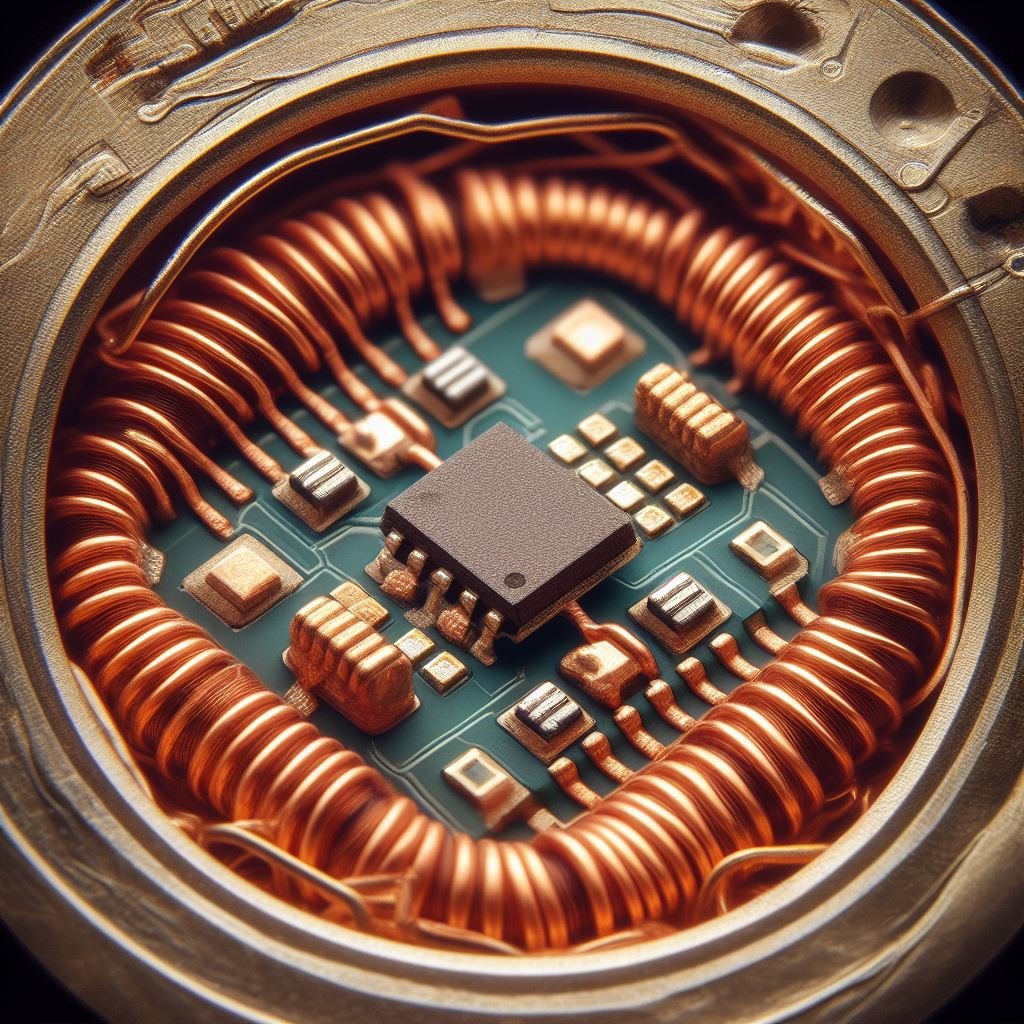

The coil, also known as an inductor or choke, on a mobile motherboard typically appears as a small, cylindrical or rectangular component. However, its appearance can vary depending on its specific design, size, and application within the circuitry.

Here are some common characteristics of mobile motherboard coils:

- Size: Coils on mobile motherboards are usually small and compact due to space constraints. They can range in size from a few millimeters to a few centimeters, depending on their power-handling capabilities and the requirements of the circuit.

- Shape: Coils may be cylindrical, rectangular, or even square in shape, depending on the manufacturer and design specifications. The shape often depends on the winding configuration and the packaging used for the coil.

- Construction: Mobile motherboard coils are typically enclosed in a protective casing made of materials such as ceramic, plastic, or epoxy resin. This casing helps protect the coil from physical damage and environmental factors.

As for recognizing coils and identifying any markings, here are some tips:

- Markings: Some coils may have markings printed directly on the casing or on a label attached to the component. These markings may include alphanumeric codes, manufacturer logos, or other identifiers. However, not all coils have visible markings, especially if they are very small or integrated into other components.

- Color: The casing of the coil may have a specific color or pattern that distinguishes it from other components on the motherboard. However, this can vary depending on the manufacturer and the materials used for the casing.

- Location: Coils are often positioned near other components such as capacitors, resistors, or integrated circuits within the circuitry. Identifying nearby components and their functions can help determine if a particular component is a coil.

- Datasheets: If possible, refer to the datasheets or technical documentation provided by the manufacturer of the mobile motherboard or the individual components. These documents may provide information about the specifications, dimensions, and markings of the coils used in the circuitry.

Overall, recognizing coils on a mobile motherboard may require careful inspection and analysis, especially if they are not clearly marked. Consulting technical documentation or seeking assistance from a qualified technician can help identify and understand the role of these components within the circuitry.

Coil For Mobile Repairing:

If the coil on a mobile motherboard is faulty or damaged, it can lead to various issues with the functioning of the mobile device. Here are some potential problems that may arise:

- Power-related Issues: Faulty coils can disrupt the power distribution within the device, leading to problems such as intermittent power loss, inability to power on, or unexpected shutdowns. This can affect the overall functionality and reliability of the device.

- Charging Problems: Coils are often used in charging circuits to regulate voltage and current flow. If the coil is defective, it can result in charging issues such as slow charging, failure to charge, or rapid battery drain. This can affect the usability and battery life of the device.

- Signal Interference: Coils are also used in signal processing circuits to filter out unwanted noise or interference. A faulty coil can disrupt signal transmission or reception, leading to issues such as dropped calls, poor network connectivity, or degraded audio quality.

- Display Problems: In some cases, coils may be used in display circuits to regulate backlighting or display power. A defective coil can result in display issues such as flickering, dimness, or complete failure of the display.

- Component Damage: In extreme cases, a faulty coil can cause damage to other components on the motherboard or within the device. This can occur if the defective coil generates excessive heat or electrical stress, leading to component failure or malfunction.

- Overheating: A damaged coil may generate excessive heat due to increased resistance or inefficient energy transfer. This can lead to localized overheating within the device, potentially causing further damage to surrounding components or affecting overall device performance.

If you suspect that the coil on your mobile motherboard is faulty, it’s essential to have it diagnosed and replaced by a qualified technician to prevent further damage to the device and ensure its proper functioning.

Coil For Mobile Repairing:

The coil on a mobile motherboard, also known as an inductor or choke, is typically manufactured using a process that involves winding a conductor material around a core material. Here’s an overview of how the coil is made:

- Selection of Materials: The first step in making a coil is to select suitable materials for the conductor and core. The conductor material is typically a metal wire with high conductivity, such as copper or aluminum. The core material may be air, ferrite, powdered iron, or other magnetic materials depending on the desired characteristics of the coil.

- Winding: The conductor wire is wound around the core material to create multiple turns or layers, depending on the specifications of the coil. The winding process can be done manually or using automated winding machines, depending on the production volume and complexity of the coil design.

- Insulation: In some cases, especially when winding multiple layers of wire, insulation may be applied between the layers to prevent short circuits and improve the overall performance of the coil. Insulation materials such as enamel, tape, or varnish are commonly used for this purpose.

- Termination: Once the winding process is complete, the ends of the wire are typically terminated with solder or other conductive materials to provide electrical connections for the coil. This allows the coil to be easily integrated into the circuitry of the mobile motherboard.

- Encapsulation: In some cases, especially for coils used in harsh environments or high-voltage applications, the completed coil may be encapsulated in a protective casing made of materials such as plastic, epoxy resin, or ceramic. This helps protect the coil from physical damage, moisture, and other environmental factors.

- Quality Control: Throughout the manufacturing process, quality control measures are implemented to ensure that the coils meet the specified electrical and mechanical requirements. This may include testing the electrical properties of the coil, inspecting for defects or inconsistencies, and verifying dimensional accuracy.

Overall, the manufacturing process for mobile motherboard coils involves precision winding techniques and careful selection of materials to produce components that meet the performance and reliability standards required for electronic devices.

Coil For Mobile Repairing:

Mobile motherboard coils, like other electronic components, are manufactured by specialized companies that produce a wide range of passive electronic components. These companies often supply components to mobile device manufacturers as part of their supply chain. Some well-known manufacturers of coils and other passive electronic components include:

- TDK Corporation

- Murata Manufacturing Co., Ltd.

- Taiyo Yuden Co., Ltd.

- Vishay Intertechnology

- Bourns, Inc.

- Coilcraft, Inc.

- Würth Elektronik

- Sumida Corporation

These companies have extensive experience and expertise in designing and manufacturing coils for various applications, including mobile devices. They offer a variety of coil types, sizes, and specifications to meet the diverse requirements of mobile motherboard designs. Mobile device manufacturers typically source coils from these specialized suppliers to ensure the quality and reliability of their products.

To protect the coil on a mobile motherboard and ensure its proper functioning, several measures can be taken:

- Proper Circuit Design: Design the circuitry on the mobile motherboard with appropriate consideration for the operating conditions and requirements of the coil. Implementing proper voltage and current regulation measures can help prevent damage to the coil.

- Overcurrent Protection: Incorporate overcurrent protection mechanisms, such as fuses or circuit breakers, in the circuitry to prevent excessive current from reaching the coil. This can help safeguard the coil against damage caused by electrical faults or short circuits.

- Transient Voltage Suppression: Install transient voltage suppression devices, such as diodes or transient voltage suppressor (TVS) components, to protect the coil from voltage spikes or surges. These devices can help clamp transient voltage spikes to safe levels and prevent them from damaging the coil.

- Environmental Protection: Ensure that the coil is adequately protected from environmental factors such as moisture, dust, and temperature extremes. Encapsulating the coil in a protective casing or conformal coating can help prevent physical damage and extend its lifespan.

- Proper Handling and Installation: Handle the coil with care during assembly and installation to avoid mechanical stress or damage to the winding. Ensure that the coil is securely mounted and connected within the circuitry to prevent vibration-induced failures or loose connections.

- Quality Control: Implement rigorous quality control measures during the manufacturing process to ensure that the coil meets specified electrical and mechanical requirements. This may include testing the coil for electrical performance, dimensional accuracy, and reliability under various operating conditions.

- Monitoring and Maintenance: Regularly monitor the performance of the coil and surrounding circuitry to detect any signs of malfunction or deterioration. Perform preventive maintenance as needed to address any potential issues and ensure the continued reliability of the coil.

By implementing these protective measures, you can help safeguard the coil on the mobile motherboard and ensure its reliable operation within the device’s circuitry.

Read More Interesting Story:

https://dotparks.com/football-game/

https://dotparks.com/transformers/

https://dotparks.com/ludo-game/

https://dotparks.com/capacitor/

https://dotparks.com/what-is-transistor/

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your article helped me a lot, is there any more related content? Thanks!

Please visit my shop https://samirsarkar.com/

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Your article helped me a lot, is there any more related content? Thanks!

Your article helped me a lot, is there any more related content? Thanks!

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article. https://www.binance.info/fr-AF/register?ref=JHQQKNKN

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://www.binance.com/join?ref=P9L9FQKY

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your article helped me a lot, is there any more related content? Thanks!

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Your article helped me a lot, is there any more related content? Thanks!